Disc springs 50CrV4 - 302 - 304 - 316

Disc springs

We’ll usually dispatch your order the same day with expected delivery within 2-4 days. This applies to all stocked disc springs

This applies to all stocked disc springs

See quantity discounts and prices by clicking on the shopping cart next to the required product.

Use the range sliders below for quick and easy navigation.

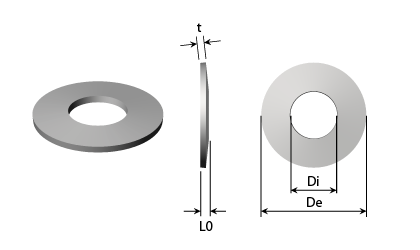

A disc spring provides great force for short travel and is therefore often used in constructions with a need for great force in minimal space. The disc spring has been designed as a conical spring washer that provides resistance when compressed, giving the spring its spring effect.

If one disc spring is not enough for the desired force and travel, it is possible to combine/stack several disc springs.

If 2 identical disc springs are inserted into each other, this provides 2 x the force and 1 x the travel.

If 2 identical disc springs are placed against each other, this provides 1 x the force and 2 x the travel.

Therefore, by combining identical stacks, you can adjust the force and the travel according to the task.

Black disc springs are phosphated and oiled. This offers some degree of protection, but does not provide definite rust protection.

Our stainless steel disc springs are made of AISI 302, AISI 304 & AISI 316 material. We recommend using these in humid or wet environments.

45-70092-description

Oiled spring steel

45-70015-description

Stainless steel 302

45-70023-description

Stainless steel 304

45-70184-description

Stainless steel 316

- 600-320-30-304In stock: 1,396Material Stainless steel 304De - External diameter (in) 0.2362Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0118L0 - Unloaded length (in) 0.0177L - Height in load F (in) 0.0134F - Force (lbs) 26.0778s - Max travel (in) 0.0043

- 00600100RFIn stock: 2,510Material Stainless steel 302De - External diameter (in) 0.2362Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0118L0 - Unloaded length (in) 0.0177L - Height in load F (in) 0.0134F - Force (lbs) 22.3572s - Max travel (in) 0.0043

- 600-320-30-316In stock: 9,492Material Stainless steel 316De - External diameter (in) 0.2362Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0118L0 - Unloaded length (in) 0.0177L - Height in load F (in) 0.0134F - Force (lbs) 26.0778s - Max travel (in) 0.0043

- 600-320-30In stock: 18,596Material Oiled spring steelDe - External diameter (in) 0.2362Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0118L0 - Unloaded length (in) 0.0177L - Height in load F (in) 0.0134F - Force (lbs) 26.7523s - Max travel (in) 0.0043

- 800-320-20-304In stock: 3,653Material Stainless steel 304De - External diameter (in) 0.3150Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0079L0 - Unloaded length (in) 0.0157L - Height in load F (in) 0.0098F - Force (lbs) 5.6202s - Max travel (in) 0.0059

- 800-320-20-316In stock: 9,555Material Stainless steel 316De - External diameter (in) 0.3150Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0079L0 - Unloaded length (in) 0.0157L - Height in load F (in) 0.0098F - Force (lbs) 5.6202s - Max travel (in) 0.0059

- 800-320-20In stock: 19,961Material Oiled spring steelDe - External diameter (in) 0.3150Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0079L0 - Unloaded length (in) 0.0157L - Height in load F (in) 0.0098F - Force (lbs) 5.8450s - Max travel (in) 0.0059

- 00800200In stock: 13,640Material Oiled spring steelDe - External diameter (in) 0.3150Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0079L0 - Unloaded length (in) 0.0157L - Height in load F (in) 0.0098F - Force (lbs) 5.8450s - Max travel (in) 0.0059

- 800-320-30-316In stock: 9,355Material Stainless steel 316De - External diameter (in) 0.3150Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0118L0 - Unloaded length (in) 0.0217L - Height in load F (in) 0.0142F - Force (lbs) 22.7057s - Max travel (in) 0.0075

- 800-320-30In stock: 19,955Material Oiled spring steelDe - External diameter (in) 0.3150Di - Internal diameter (in) 0.1260t - Thickness (in) 0.0118L0 - Unloaded length (in) 0.0217L - Height in load F (in) 0.0142F - Force (lbs) 23.4476s - Max travel (in) 0.0075

Thicknesses of finished disc springs may measure less than the specified thickness as the specified thickness is before machining.

Stainless steel 304: W. Nr. 1.4301

Stainless steel 316: W. No. 1.4401

All our disc springs are magnetic - including those in AISI 316. This is due to the way they are produced. If non-magnetic disc springs are desired, please contact us at: [email protected]

Springs are dimensioned according to DIN 2093. The dimensions in the catalogue are unmachined measurements. Therefor measurements may differ from those in the catalogue tables. This applies to diameters and thickness.

The force is calculated theoretically. It is intended as a guide, with scope for large tolerances.

The springs 50 CrV4 & Stainless 304 & stainless 316 are dimensioned according to DIN 16983, which gives the following tolerances.

The force is calculated theoretically. It is intended as a guide, with scope for large tolerances.

If you want a PDF datasheet or a 3D CAD drawing of the spring in .step, .iges or .sat format, these can be downloaded for free by clicking on the 3D CAD symbol next to the item number in the table.

The service life of a spring is generally very difficult to define. A large number of parameters come into play, and it is therefore impossible to define a service life.

Parameters with a significant influence on service life include: Installation, installation method, number of movements, vibrations, shocks, torsion, length of travel, non-axial travel, temperature, wear against other surfaces, environment of use, any cleaning agents, lateral impacts, etc.

Applying the maximum load to the spring or exceeding it will shorten its service life and may cause it to become permanently distorted.

Internet Explorer Incompatibility

This website unfortunately does not work well with Internet Explorer. We recommend using one of the following free browsers: