Gas Springs Made of Stainless Steel | Reducible Force

Variload gas springs have the same physical dimensions as standard gas springs. It is also possible to reduce the force, but it is not possible to re-fill it yourself. Variload springs are delivered with maximum force. Gas can be released by means of a small valve. Please note that to re-fill the gas spring, it must be send back to production.

Both tube and piston rod are made of 304 stainless steel.

This series also exists in a black painted version that can be used in a dry environment.

90-70023-description

Stainless steel 304

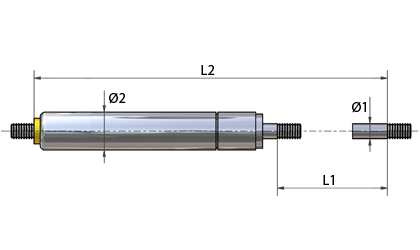

- VLRF-6-50-400In stock: 8Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 1.9685L2 - Unloaded length between thread (in) 6.0630F - Force (lbs) 89.9236K - Force ratio 1.3300G - Thread (in) 0.2362

- VLRF-6-60-400In stock: 5Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 2.3622L2 - Unloaded length between thread (in) 6.6142F - Force (lbs) 89.9236K - Force ratio 1.3300G - Thread (in) 0.2362

- VLRF-6-75-400In stock: 1Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 2.9528L2 - Unloaded length between thread (in) 8.4252F - Force (lbs) 89.9236K - Force ratio N/AG - Thread (in) 0.2362

- VLRF-6-80-400In stock: 2Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 3.1496L2 - Unloaded length between thread (in) 8.2283F - Force (lbs) 89.9236K - Force ratio N/AG - Thread (in) 0.2362

- VLRF-6-90-400In stock: 5Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 3.5433L2 - Unloaded length between thread (in) 10.6299F - Force (lbs) 89.9236K - Force ratio N/AG - Thread (in) 0.2362

- VLRF-6-100-400In stock: 6Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 3.9370L2 - Unloaded length between thread (in) 9.7638F - Force (lbs) 89.9236K - Force ratio 1.3300G - Thread (in) 0.2362

- VLRF-6-120-400In stock: 7Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 4.7244L2 - Unloaded length between thread (in) 11.1024F - Force (lbs) 89.9236K - Force ratio 1.3300G - Thread (in) 0.2362

- VLRF-6-140-400In stock: 2Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 5.5118L2 - Unloaded length between thread (in) 13.7795F - Force (lbs) 89.9236K - Force ratio 1.3300G - Thread (in) 0.2362

- VLRF-6-150-400In stock: 4Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 5.9055L2 - Unloaded length between thread (in) 13.7402F - Force (lbs) 89.9236K - Force ratio 1.3300G - Thread (in) 0.2362

- VLRF-6-170-400In stock: 6Material Stainless steel 304Ø1 - Piston Rod diameter (in) 0.2362Ø2 - Tube diameter (in) 0.5906L1 - Stroke (in) 6.6929L2 - Unloaded length between thread (in) 15.5906F - Force (lbs) 89.9236K - Force ratio N/AG - Thread (in) 0.2362

Cylinder and piston rod: Stainless steel gas springs are made from AISI 304L stainless steel.

Oil: The oil is a common lubrication oil, but is not approved for food use. We can supply gas springs for use with foodstuffs. Contact us if you require such a solution.

Gas: The gas is nitrogen gas.

Variload gas springs can be refilled for a fee.

The force in a compression gas spring increases the more it is compressed, in other words as the piston rod is pushed into the cylinder. This is because the gas in the cylinder is compressed more and more due to displacement changes inside the cylinder, thereby increasing the pressure that results in the axial force that pushes the piston rod.

Variload gas springs are basically constructed in the same way as standard gas springs. Variload gas springs are filled with the highest possible pressure of nitrogen gas.

Variload gas springs are equipped with a valve that can release pressure from the cylinder. By releasing pressure, the force of the gas spring can be reduced to the pressure required for a particular construction. When the spring is to be adjusted, please ensure no damage occurs due to an excess of pressure being released.

When adjusting the pressure, it is recommended that you add an extra weight corresponding to +10% of the item's weight before carrying out the adjustment. When the pressure of the gas spring is to be adjusted, open the valve using the accompanying Allen key. Carefully unscrew the valve slightly until you can hear gas escaping. Do not unscrew the valve fully. Until the correct pressure is reached, it is recommended that you tighten the valve at regular intervals in order to test the force of the gas spring.

You can always release a little more - but you can't put more in.

Please note that even a small amount of pressure escaping can have a major impact on the force of the gas spring. Once the correct pressure has been found, remove the 10% extra weight and test again.This prevents too much pressure being released. If two Variload gas springs are being used in a construction, it is recommended that you release pressure from the valves in turn a little at a time, thus ensuring that the final pressure in the two Variload gas springs is as equal as possible.

Gas springs contain nitrogen gas under high pressure. This is a type of gas that cannot burn or explode, nor is it toxic if inhaled. No attempt must be made, in any circumstances, to take the gas spring apart or to refill it - this is extremely risky due to the high pressure! Do not burn, puncture, squash or dent the gas spring, and do not weld the surface of the cylinder. Do not scratch, paint or bend the piston.

Never use gas springs as a safety device. If damage to a gas spring could result in personal injury, provision must be made for this by means of a safety device. Alternatively, use a safety gas spring. Call for further information.

Gas springs must be stored and fitted with the piston pointing downwards and at 45 degrees to the horizontal. This is important, as this fitting will ensure that internal glands will remain lubricated by the oil inside the gas spring.

If a gas spring is fitted horizontally or with the piston upwards, the oil will run out of the glands, and thus wear and leaking glands will be the result of incorrect fitting. For each fitting you must ensure that there is no sideways deflection or other forces that will affect the gas spring in any way other than free axial movement in the gas spring's longitudinal direction.

Always use the shortest possible travel, and select the biggest possible cylinder diameter - this increases durability. Long thin gas springs will be considerably weaker than short fat ones.

Always fit stainless steel gas springs in places exposed to a damp environment or for use in the food industry. Note that the oil in the gas spring is not approved for use in the food industry.

Do not, therefore, fit gas springs directly over production, as a worn gas spring can leak oil. There is no need to lubricate the piston, as the spring is maintenance-free. Do not expose the gas spring to vibrations.

Gas springs are designed to perform no more than 5 strokes per minute at 20 °C. If this is exceeded, there will be a build-up of heat inside the gas spring that may result in leaky glands. Gas springs are designed to keep to 30,000 movements when fitted correctly.

It is recommended that physical stops always be used in constructions. This will ensure that the gas spring is not used with loads in excess of those for which it was designed. Movement of the gas spring is only dampened for the last section against the full extension of the piston.

Gas springs will lose pressure slightly over time, compared with the original pressure at the time they were fitted. A pressure loss of up to 10% may be expected.

It is recommended that you continue to ensure that the function of the gas spring complies with construction requirements. If in doubt, replace the gas spring. It is recommended that both gas springs be replaced if they work in pairs. A variation in pressure in gas springs working in pairs will result in a shorter service life for the gas springs.

Our gas springs work best in temperatures between -30 °C and +80 °C. Using the springs in temperatures close to those limits will produce an altered force, and maximal usage cannot be recommended. The compressed force of the gas springs is higher than the force in the extended position. The end force Fn is calculated by multiplying the initial force by the force quotient of the gas spring in question. Gas springs are filled at 20 °C, and the initial force is therefore measured at 20 °C. The force will change by approximately 3-3.5% per 10 °C. Tolerances on extended length dimensions are +/-2 mm.