Premium ISO Die springs

Premium ISO Die springs

We’ll usually dispatch your order the same day with expected delivery within 2-4 days. This applies to all stocked die springs

See quantity discounts and prices by clicking on the shopping cart next to the required product.

Use the range sliders below to navigate around our large selection of Premium ISO die springs quickly and easily.

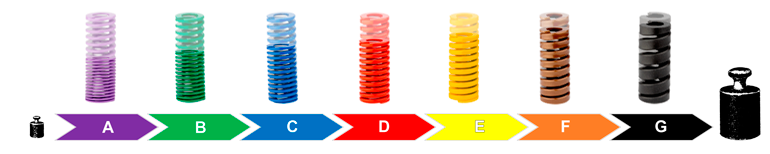

Premium ISO die springs are manufactured in Italy. The springs are made using wire that is of a higher quality than prescribed in DIN 10243. In addition, during production the die springs have been pre-pressed and shot peened and then painted in one of 7 different colours, each representing its own category of travel and strength.

In addition to the 4 usual strength categories, with this range we can also offer 3 new categories of die springs. The range (Yellow, Red, Blue, Green) is manufactured in accordance with the ISO 10243 standard, which guarantees high quality. The range (Purple, Copper and Black) is manufactured in exactly the same way as the ISO range and therefore also maintains the same high quality.

The purple category has been added at the weak end of the scale. If you need a long distance of travel, but still want plenty of force, then this is the right category for you.

At the other end we have added the copper and the black categories. This is where the spring strength is really turned up! The distance of travel is not long, but the strength is high!

The wire is rectangular, but still has rounded edges. The rectangular wire gives the spring greater force than a regular compression spring. One characteristic of die springs is the large force and short spring travel.

If a spring with either more or less force is required, a spring with the same dimensions – but with a different colour code – can be used, as the spring has the same installation dimensions.

Die springs are available with a maximum force (Fn) from 20.6824 lbfN to 10,116.402 lbf.

Premium ISO die springs can be used in many different applications that require large forces in a confined space, which is typically the case in the tool industry or in constructions where high force is required.

Note that the colour coding is not necessarily the same for RG die springs, ISO and Premium ISO die springs.

- G1020In stock: 46Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 0.7874R - Spring constant (lb/in) 3,311.8822S1 - Travel at F1 (in) N/AL1 - Length at F1 (in) N/AF1 - Force in N at S1 (lbs) N/ASn - Maximum travel (in) 0.0866Ln - Max. loaded length (in) 0.7008Fn - Maximum load at Ln (lbs) 281.0112

- A1025In stock: 80Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 0.9843R - Spring constant (lb/in) 48.5362S1 - Travel at F1 (in) 0.3465L1 - Length at F1 (in) 0.6378F1 - Force in N at S1 (lbs) 16.6359Sn - Maximum travel (in) 0.4921Ln - Max. loaded length (in) 0.4921Fn - Maximum load at Ln (lbs) 23.8297

- C1025In stock: 139Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 0.9843R - Spring constant (lb/in) 91.3623S1 - Travel at F1 (in) 0.2480L1 - Length at F1 (in) 0.7362F1 - Force in N at S1 (lbs) 22.4809Sn - Maximum travel (in) 0.3701Ln - Max. loaded length (in) 0.6142Fn - Maximum load at Ln (lbs) 33.7213

- D1025In stock: 179Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 0.9843R - Spring constant (lb/in) 131.3333S1 - Travel at F1 (in) 0.1969L1 - Length at F1 (in) 0.7874F1 - Force in N at S1 (lbs) 25.8530Sn - Maximum travel (in) 0.2953Ln - Max. loaded length (in) 0.6890Fn - Maximum load at Ln (lbs) 38.8919

- E1025In stock: 137Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 0.9843R - Spring constant (lb/in) 210.1332S1 - Travel at F1 (in) 0.1693L1 - Length at F1 (in) 0.8150F1 - Force in N at S1 (lbs) 35.0702Sn - Maximum travel (in) 0.2480Ln - Max. loaded length (in) 0.7362Fn - Maximum load at Ln (lbs) 51.7061

- F1025In stock: 141Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 0.9843R - Spring constant (lb/in) 953.5937S1 - Travel at F1 (in) 0.0984L1 - Length at F1 (in) 0.8858F1 - Force in N at S1 (lbs) 93.9701Sn - Maximum travel (in) 0.1496Ln - Max. loaded length (in) 0.8346Fn - Maximum load at Ln (lbs) 140.7304

- G1030In stock: 49Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 1.1811R - Spring constant (lb/in) 2,055.6510S1 - Travel at F1 (in) N/AL1 - Length at F1 (in) N/AF1 - Force in N at S1 (lbs) N/ASn - Maximum travel (in) 0.1378Ln - Max. loaded length (in) 1.0433Fn - Maximum load at Ln (lbs) 281.0112

- A1032In stock: 183Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 1.2598R - Spring constant (lb/in) 37.1159S1 - Travel at F1 (in) 0.4409L1 - Length at F1 (in) 0.8189F1 - Force in N at S1 (lbs) 16.4111Sn - Maximum travel (in) 0.6299Ln - Max. loaded length (in) 0.6299Fn - Maximum load at Ln (lbs) 23.3801

- B1032In stock: 196Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 1.2598R - Spring constant (lb/in) 48.5362S1 - Travel at F1 (in) 0.3780L1 - Length at F1 (in) 0.8819F1 - Force in N at S1 (lbs) 18.4343Sn - Maximum travel (in) 0.5039Ln - Max. loaded length (in) 0.7559Fn - Maximum load at Ln (lbs) 24.5042

- C1032In stock: 176Dh - Min. hole (in) 0.3937Dd - Max shaft (in) 0.1969L0 - Unloaded length (in) 1.2598R - Spring constant (lb/in) 74.2318S1 - Travel at F1 (in) 0.3150L1 - Length at F1 (in) 0.9449F1 - Force in N at S1 (lbs) 23.3801Sn - Maximum travel (in) 0.4724Ln - Max. loaded length (in) 0.7874Fn - Maximum load at Ln (lbs) 35.0702

52SiCrNiV6 steel.

The wire is stretched, heat treated and shot peened before painting.

Working temperature between -30 ºC and +250 ºC.

These springs are not stainless steel.

Spring constant ( R ): +/- 10%

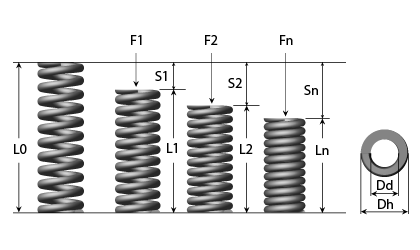

Minimum hole (Dh): The external diameter is always less than the specified value for Dh.

Maximum shaft (Dd): The internal diameter is always greater than the specified value for Dd.

If you want a PDF datasheet or a 3D CAD drawing of the spring in .step, .iges or .sat format, these can be downloaded for free by clicking on the 3D CAD symbol next to the item number in the table.

The colour labelling is done by powder coating without a special protection from corrosion.

The springs are divided into colour groups according to the strength of the springs.

- The weaker a spring, the longer the potential travel.

- The more force you need, the shorter the travel you can get.

Usually right. The force and application is not affected by the direction of wind.

Standard die springs are not defined with a specific direction of wind. Depending on production, the springs may be either right or left wound.

The service life of a spring is generally very difficult to define. A large number of parameters come into play, and it is therefore impossible to define a service life. Parameters with a significant influence on service life include: Installation, installation method, number of movements, vibrations, shocks, torsion, length of travel, non-axial travel, temperature, wear against other surfaces, environment of use, any cleaning agents, lateral impacts, etc.

The maximum force (Fn) and/or maximum travel (Sn) should not be exceeded, as this reduces the service life significantly. To avoid uncontrolled dynamic stress, die springs should always be fitted with a specific initial tension.

The longest service life is achieved with load and travel of max. 25% of the free length (L0).

If die springs in cars or other applications are fitted or replaced with our die springs, Sodemann-Springs.Us cannot be held responsible for any differences in performance or damage.

This also applies to customers who visit Sodemann-Springs.US and get help and/or guidance.

It is not possible to get custom-made die springs.

Internet Explorer Incompatibility

This website unfortunately does not work well with Internet Explorer. We recommend using one of the following free browsers: